Our expertise in performance elastomers, design engineering and fully-automated rubber molding delivers on quality, value and peace of mind far beyond that of traditional rubber molders.

PERFORMANCE ELASTOMER MATERIALS

COLLABORATIVE ENGINEERING

AUTOMATED MOLDING + OVERMOLDING

PRODUCT

DESIGN

RAPID

PROTOTYPING

PROJECT

MANAGEMENT

Transportation

Automotive + e-Mobility

Poly-Nova’s fully-automated rubber molding technology delivers exacting quality, value and peace of mind. Our ability to combine multiple materials into one single component will improve your product and process by making parts that are easier to handle and assemble. We can also reduce the content of high-end rubber materials by incorporating other less costly rigid materials such as plastics or metals.

Poly-nova’s Performance Elastomer Compounds address many of the automotive industry’s toughest challenges including high voltage, friction, permeation, temperature and aggressive chemical and fuel exposure requirements.

Energy Technology

Transmission + Distribution

In a rapidly changing energy industry, we provide stable services to the Power Transmission and Distribution market, including performance materials, product engineering and design assistance, testing and rubber injection molding, and rubber overmolding.

Product categories include:

• Distribution Insulators

• Transmission Insulators

• Arrestor Housings

• Vacuum Recloser Housings

• Insulator Sheds

• Line Post Insulators

• Cold-Shrink Tubing

Life Sciences

Pharma + Diagnostics

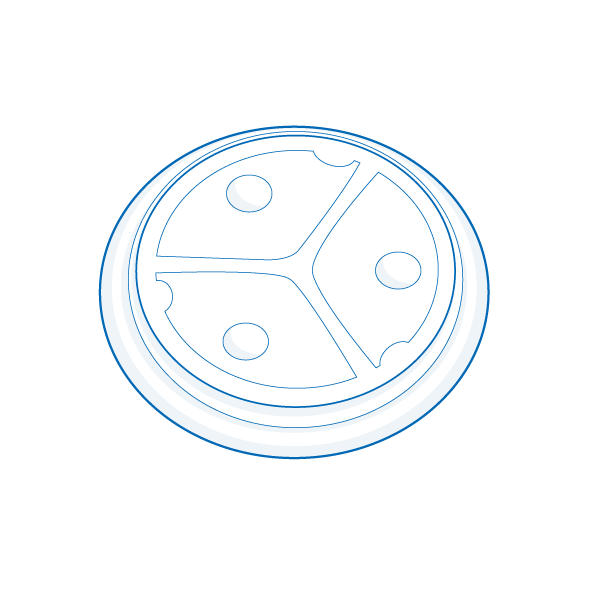

Fully automated molding and overmolding of Fluoroelastomer (FKM), EPDM, Isporene, Silicone and Fluorosilicone (FVMQ), create numerous advantages for the Pharmaceutical, Hygiene and Diagnostic industries where accuracy, precision and cleanliness are most critical.

End-to-End Development Partner

Collaborative support at each phase of your design cycle.

From Ideation

Part functionality and quality are critical factors in the design process. Poly-Nova’s specialized team of Design Engineers is on-hand to assist in creating a product that meets both your technical and functional requirements. We work closely with you to ensure our solution becomes part of your success.

To Manufacturing

Utilizing Design for Manufacturability (DFM) processes and tools such as Finite Element Analysis (FEA) and Computer Tomography (X-RAY), we create and test part designs to ensure their performance is as intended.

2017 Rubber Industry Executive of the Year