Poly-Nova provides in-depth knowledge and experience in all aspects of product design, material development, mold design and advanced manufacturing. Utilizing Advanced Product Quality Planning (APQP) at each stage of development ensures delivery of comprehensive solutions for the most demanding technical rubber applications.

PRODUCT

DESIGN

PROTOTYPE

TOOLING

RAPID PROTOTYPING

MATERIALS

TECHNOLOGY

ADVANCED

MANUFACTURING

QUALITY

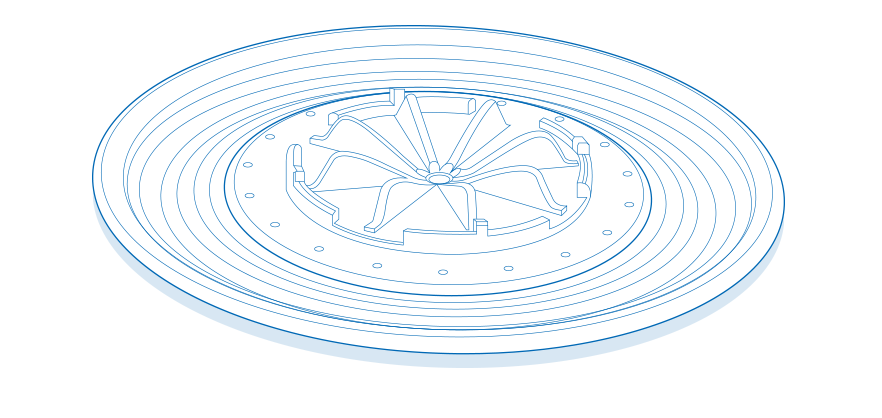

Product Design

Part functionality and quality are key factors in design. Poly-Nova’s Design Engineers work closely with your team in creating a product that meets your precise technical and functional requirements. Working closely with you to ensures that our solution becomes part of your success.

Efficiency in Design

Utilizing Design for Manufacturability (DFM) processes and tools such as Finite Element Analysis (FEA) and Computer Tomography (X-RAY) we create and test part designs to ensure their performance is exactly as intended.

Prototyping

Poly-Nova’s prototyping focus ensures our customers are supplied with production – quality parts – within a short timeframe – to accommodate design and functional testing for verification in the final production design.

Prototyping Materials

- Butyl Rubber

- EPDM

- FluoroElastomer (FKM)

- Fluorosilicone (FVMQ)

- Hydrogenated Nitrile Rubber

- Natural Rubber

- Nitrile Rubber (NBR)

- Polychloroprene Rubber (CR)

- Silicone (VMQ)

Overmolding/Bonding Materials

- Aluminum

- Brass

- Carbon Steel

- Composite FRP Rods

- Copper

- Die Cast Aluminum

- Die Cast Zinc

- Engineered Resins

- Filled Nylons

- Iron

- Nylon (Mineral or Glass Filled)

- Polyamides

- Polyester

- Stainless Steel

Prototype Tooling

Our prototype tools are built to the same high standards as our production tools. This approach allows the simulation of a true production environment to create more accurate, production-ready parts, resulting in lowered overall development costs and faster product to market times for you.

Prototyping Capabilities

- Precision engineering detail including complex shapes, profiles and aggressive tolerances.

- Quick turnaround to support design and functional testing.

- Creation of true production – quality parts.

- Dedicated prototype presses and lab facilities.

- Development of over-molding and bonding processes to substrates such as engineering grade plastics (PA, PPA, PPS, FEP, PTFE), metals and composites.

High-performance Elastomers

Poly-Nova’s team of Chemical Engineers formulate, develop and test custom elastomer compounds on premise to ensure you receive a material that meets the most demanding needs of your application. We ensure it performs as intended, and is easily processable.

Material Library

Poly-Nova’s material library contains thousands of innovative elastomer compounds currently in use, in a wide variety of industries and applications ranging from Aerospace to Pharmaceutical.

We Develop the Following Elastomers

- Butyl Rubber

- EPDM

- FluoroElastomer (FKM)

- Fluorosilicone (FVMQ)

- Hydrogenated Nitrile Rubber (HNBR)

- Natural Rubber

- Nitrile Rubber (NBR)

- Polychloroprene Rubber (CR)

- Silicone (VMQ)

Specialty Elastomers for

- Low-Friction

- Low-Permeation

- High Temperature

- Low Temperature

- Chemical Exposure

- Fuel Exposure

- High voltage

- Hydrophobicity

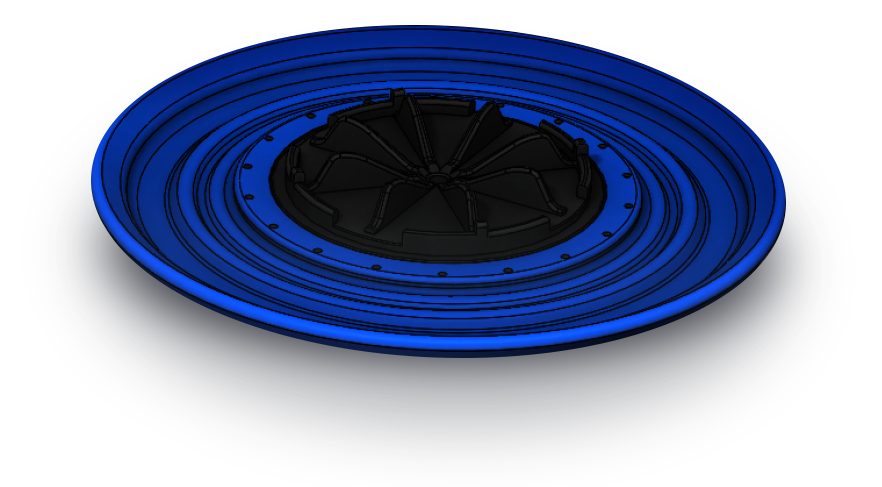

Advanced Manufacturing

The world doesn’t need another traditional rubber molder.

We are committed to pushing past traditional manufacturing practices. Poly-Nova develops new and unique automation, overmolding, molding and bonding technologies aimed at creating the highest quality rubber components for maximal in economic efficiencies.

Our fully automated rubber molding and rubber overmolding systems deliver the absolute highest part quality, thereby eliminating secondary finishing operations for outstanding cost-effectiveness.

Precise and efficient.

Poly-Nova’s fully automated rubber overmolding process combines our flashless molding technology with fully automated insert loading, demolding and inspection. Finished components are mechanically and chemically bonded and meet the most exacting quality, technical and cost requirements. This process requires no finishing operations and is ideally suited for use with high performance elastomers such as fluorosilicone, fluoroelastomer and co-polymer materials.

We Overmold to the Following Substrates

- Aluminum

- Brass

- Carbon Steel

- Composite FRP Rods

- Copper

- Die Cast Aluminum

- Die Cast Zinc

- Engineered Resins

- Filled Nylons

- Iron

- Nylon (Mineral or Glass Filled)

- Polyamides

- Polyester

- Stainless Steel

We Overmold the Following Elastomers

- Butyl Rubber

- EPDM

- FluoroElastomer (FKM)

- Fluorosilicone (FVMQ)

- Hydrogenated Nitrile Rubber (HNBR)

- Natural Rubber

- Nitrile Rubber (NBR)

- Polychloroprene Rubber (CR)

- Silicone (VMQ)

Quality

At Poly-Nova, we know that commitment to quality is at the very core of business excellence.

As part of the starlim//sterner group, we have harmonized and developed an integrated management system that includes quality, health and safety, and environmental best practices.

This system is certified to meet standards and ensures consistency and efficiency at every phase of our business practice for the following:

Our sustained commitment to continually improving this system directly translates to value for your company.